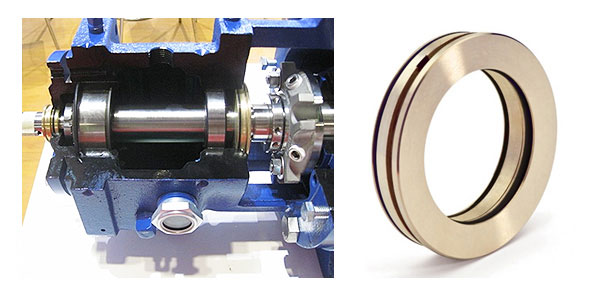

It consists of a rotor and a stator, which are unitized by an O-ring, so that the two parts will not be separated during the operation. Typically, the rotor turns with the shaft, and the stator is pressed into the bearing housing. The two components interact to keep the pollutants out of the bearing housing and prevent the leakage of the lubricants , even when the equipment is shut down. The sealing performance of the Bearing Isolator will not degrade over time, which will enable it to provide life-time bearing protection for the rotating equipment.

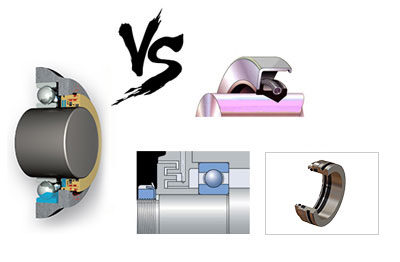

| 轴承隔离器蒸汽阻挡环静态和动态对比 | Lip Seal | Labyrinth Seal | Magnetic Seal | Bearing Isolator | |

▶ 更多优势 |

|

3000hours | Infinite | 2years | Infinite |

| Shaft Damage | Yes | No | No | No | |

| Oil Leakage | No | No | No | Yes | |

|

Power Consumption (Wearing) |

Yes | No | Yes | No | |

| Equipment Wash-Down | No | No | No | Yes | |

| Dust/Dirt | Yes | No | Yes | Yes | |

| Steam/ Humidity/ Condensation | No | No | Yes | Yes |

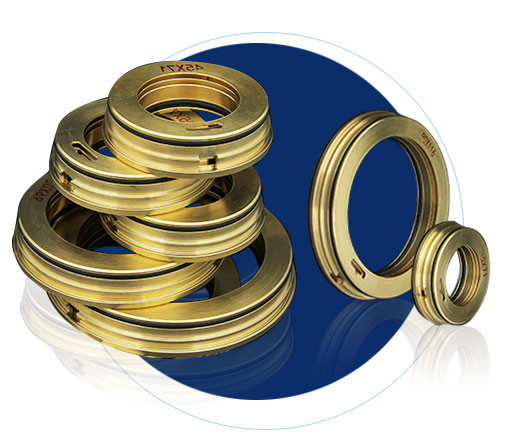

Committed to high quality sealing products research and development. We have supplied bearing isolators and various sealing products to many OEM manufacturers of ANSI, ISO and API 610 chemical pump, IEEE - 841 motor, high frequency motor, fan, reducer, mixer, pillow block, turbine, screw conveyor, etc. BRS seals are custom-engineered to each application, ensuring that the best combination of materials and design provide the most effective sealing solution.

IEEE-841 motor standard specified sealing choice

High efficiency motor, mining motor and wind energy motor preferred

Combined with the conductive fiber axial grounding technology, prevent high frequency motor bearings damage from shaft voltage

API610 pump standard specified sealing choice ISO, ANSI chemical pump, nuclear pump standard configuration

Stainless steel, PTFE, aluminum material are available for corrosion environment Spit design for easy installation

Different design for splash, immerged or forced oil lubrication

Special design for high or low speed, shaft movement

Zero leakage, maintenance free, no damage to shaft

Roller bearing, sleeve bearing, magnetic bearing, all applicable

Solve the sealing challenge of shaft movement, heavy pollution

Zero leakage, maintenance free, reusable

Workplace safety is a top concern in the chemical industry, especially when hazardous chemi…

When the equipment manufacturer chooses the bearing, it will fully consider the bearing ser…

High temperature, strong vibration, high humidity, heavy pollution environment is the seali…

Down-hole motor, conveyor belt, reducer sealing preferred 2. Zero leakage, free maintenanc…

Zero leakage, pollution-free, maintenance-free 2. Adapt to shaft Large deflection, run-out…

友情链接: 青岛网络公司